Stratasys

450 Case Studies

A Stratasys Case Study

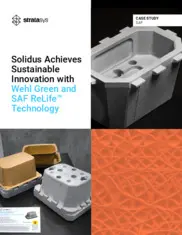

Solidus, a European leader in laminated solid board packaging committed to the “Zero Plastics” initiative, needed a faster, more flexible way to design and prototype complex MAP and top‑seal trays. Traditional CNC aluminum machining was slow, costly, and limited innovation, so Solidus turned to Stratasys’ SAF technology — specifically the SAF ReLife process deployed through partner Wehl Green — to meet its sustainability and rapid‑iteration needs.

Wehl Green used Stratasys SAF ReLife to repurpose waste powder into high‑quality molds and parts, including a SAF ReLife mold now producing up to 6,000 cardboard packages per hour on Solidus’ line. The Stratasys SAF solution accelerated design iteration, eliminated costly CNC prototyping, delivered significant cost savings, and achieved up to a 90% reduction in carbon footprint versus production with fresh materials, while improving delivery reliability and collaboration.